Graphene is a promising graphitic material showing high conductivity, large surface area and excellent mechanical properties. Because of its unique characteristics, graphene based reasearch is gaining much attention recently. There are different top down and bottom up approaches known for the synthesis of graphene. Among these techniques, synthesis of graphene from graphite is a highly reliable and widely used top down approach.

What is graphite?

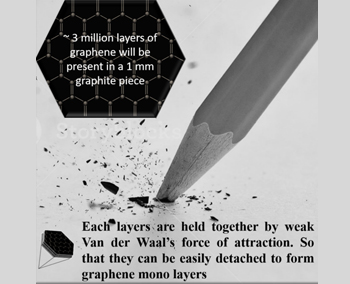

Graphite is a naturally occurring allotrope of carbon. It is formed by the stacking of two-dimensional graphene layers one over the other. There are different methods known for the exfoliation of graphite to graphene layers which include, mechanical exfoliation, micro wave assisted exfoliation and liquid phase exfoliation. Liquid phase exfoliation is further divided into two categories such as cavitation-based exfoliation and by means of electrochemical reactions.

Exfoliation of graphite to graphene

Mechanical exfoliation:

During 2010, two eminent scientists Andre Geim and Konstantin Novosolov received Nobel prize for their ground breaking experiments regarding graphene. They implemented a simple mechanical exfoliation technique using scotch tape for separating the graphene layers from graphite. This involves pasting a piece of adhesive tape over graphite piece and then pulling it back. This will help to produce single layer graphene. However, this method is not suitable for large scale production of graphene.

Exfoliation using microwaves:

Exposing expandable graphite under microwave radiation can help in the mass production of exfoliated graphite within few minutes. This is because, due to conductive nature, graphite can strongly interact with micro waves and produce hot plasma. For that, the expandable graphite should be sealed in a glass vial or crucible and exposed to microwave.

Liquid phase exfoliation:

Liquid phase exfoliation of graphite can be performed in two different ways such as by means of cavitation formation and by electrochemical method. Exfoliation by cavity formation can be done by ultrasonication method. For that, a suitable solvent is selected and graphite is dispersed in it. Later sonication is performed using either bath or probe sonicator. Solvent will get intercalated between the graphene layers and as the time of sonication progress bubbles will be produced in the solution. These bubbles will collapse and the force generated by bubble collapsing help to displace and detach the graphene layers.

The electrochemical exfoliation of graphite is done in a suitable electrolyte. The most commonly used electrolytes are ammonium sulphate and sulphuric acid. There should be two electrodes, one as counter electrode and the other as working electrode. The counter electrode should be an inert electrode and the graphite rod which should be exfoliated will be taken as the working electrode. With the application of voltage, the electrochemical reaction will progress and the electrolyte will get dissociated. The ions produced by dissociation of electrolyte will be intercalated between the graphene layers and then ultimately results in exfoliation. this is evident by the change in colour of the electrolyte solution from colour less to black.